Business Continuity Management

Business Continuity Plan

GlobalWafers demonstrates strong operational resilience and ensures stable and reliable services through its Business Continuity Plan (BCP), even in the event of natural disasters, unexpected incidents, or supply chain disruptions. Through systematic risk assessments, preventive measures, and cross-site coordination mechanisms, we minimize the impact of operational interruptions and uphold our long-term commitments to customers and partners.

Purpose of BCP/Scope of Application

This Business Continuity Plan (BCP) aims to ensure that, in the event of major emergencies, our global sites can work collaboratively through coordinated backup mechanisms to restore critical operations in the shortest possible time. It seeks to minimize impacts on product supply, manufacturing progress, and customer service, thereby maintaining stable and reliable global supply capabilities.

Business Continuity Policy and Objective

GlobalWafers is committed to establishing an effective Business Continuity Management (BCM) System to ensure the company’s resilience in responding to various disasters or operational disruptions, thereby safeguarding the shared interests of the Company, customers, and stakeholders.

Objectives and Scope of GlobalWafers’ Business Continuity Management System:

- Protect Safety:Prioritize personnel safety above all.

- Ensure Continuity:Strengthen organizational and supply chain resilience to maintain uninterrupted critical operations and enable rapid recovery, minimizing operational impact.

- Protect Assets:Safeguard the integrity and security of key assets, including technology, information, and physical resources.

- Continuous Improvement:Comply with regulatory requirements and ensure ongoing effectiveness of the plan through continuous self-assessment and regular drills.

GlobalWafers’ business continuity management framework, including related functional organizations and execution processes, is defined in the “GWC Group Business Continuity Plan Procedure.” Business continuity management is a shared responsibility of the company’s management team and all employees.

Business Continuity Management

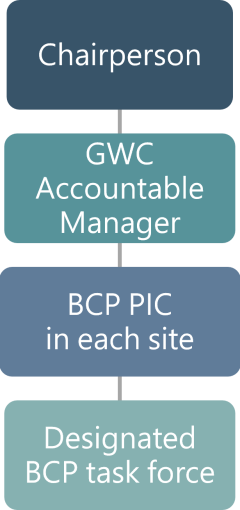

According to GlobalWafers’ Emergency Response Procedure for Operational Crises, when an emergency occurs, the Chairperson will assess the scale and severity of impacts reported by each site, and will make comprehensive decisions and provide oversight. The GlobalWafers Accountable Manager is responsible for coordinating resources and communication across departments and sites. Each site has a designated BCP Person-in-Charge (PIC) to ensure that the Business Continuity Plan is effectively executed based on local site conditions. In addition, each site’s Designated BCP Task Force (the Emergency Response Team) is responsible for implementing and enforcing the required actions. Through this top-down decision-making framework and bottom-up information reporting mechanism, the organization can respond to emergencies in real time and ensure the effective operation of the business continuity management system.

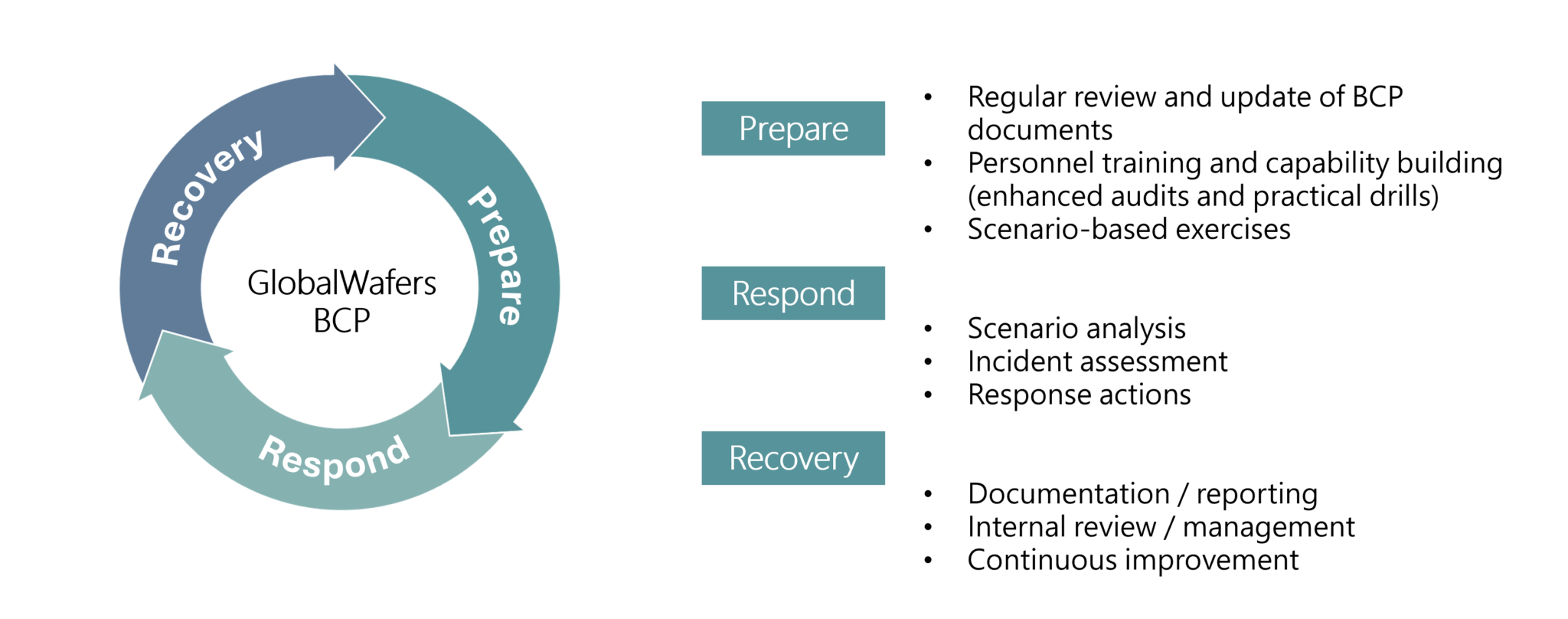

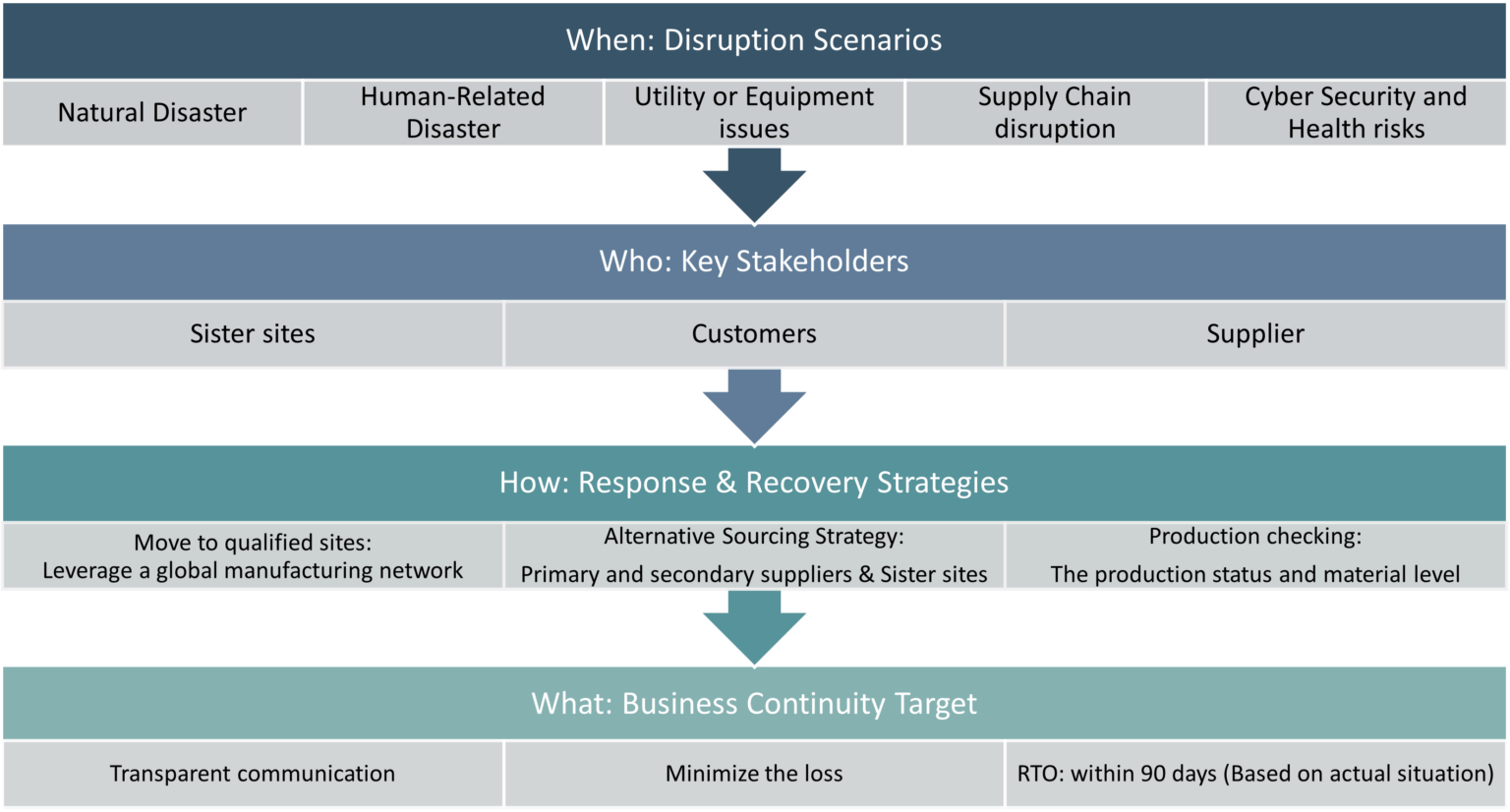

The BCP management framework is built on three core cyclical processes—Prepare, Respond, and Recover. Measures are implemented according to the nature of impact under various scenarios, including natural disasters, man-made incidents, equipment or utility failures, supply chain disruptions, cybersecurity threats, and health-related risks. The objective is to restore normal operations in the shortest possible time. After the incident ends, documentation and reporting are conducted, followed by internal review and improvement actions to continually enhance organizational resilience and ensure stable products and services for our customers.

GWC Group Reporting System

BCM Process Diagram

Operation Disruption Response Flowchart

Training & Drill

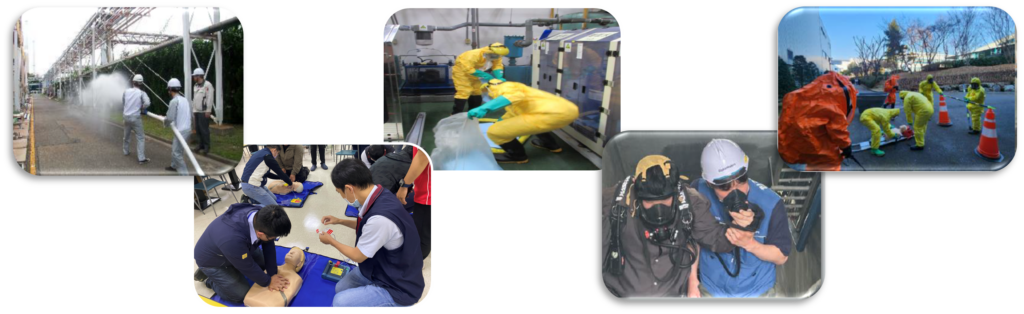

GlobalWafers conducts emergency response drills annually, covering various themes with at least one exercise each year. Training items include hands-on operation of emergency response equipment, drills for handling toxic chemical and chemical spills, CPR, Heimlich maneuver first-aid training, as well as fire extinguishing, emergency evacuation, and other response exercises. Through these trainings, employees strengthen their familiarity and practical skills in evacuation, first aid, and various emergency procedures. These exercises not only enhance cross-departmental collaboration and coordination but also establish a continuous improvement process to ensure ongoing enhancement of overall emergency response effectiveness. At the same time, the company emphasizes the concept of “responsibility shared by all,” ensuring that every employee fully understands the importance of the Business Continuity Plan (BCP) and is able to perform their expected roles and responsibilities during emergencies. This enables timely handling of emergency incidents in the facilities and prevents the escalation of disasters.

Supply Chain Continuity

In terms of business continuity management within procurement, GlobalWafers maintains a list of qualified suppliers and components, updating it regularly to monitor risk levels and ensure the stability of supply sources. For key materials, GlobalWafers has implemented enhanced risk management measures, including supplier audits, conflict-free mineral requirements, Business Continuity Plan (BCP) self-assessment, and the establishment of second-tier suppliers. Additionally, the company maintains a certain level of safety stock internally.