Message from the Chairperson

The drastic changes in the world over the past few years have further highlighted the importance of corporate social responsibility. Facing global challenges such as the impact of the pandemic, geopolitical conflicts, and extreme weather, achieving a balance in economic, social, and environmental aspects is a critical issue for enterprises. As a member of the semiconductor industry, GlobalWafers understands that sustainable development is not just about corporate profitability but also about building a more stable and harmonious future for the next generation. GlobalWafers upholds the concept of responsible growth and is committed to striking a balance between economic, social, and environmental aspects. We will continuously work to embody these values, establishing a strong corporate foundation through sustainable practices in an uncertain environment.

GlobalWafers aspires to be a positive force in shaping a sustainable environment. Our series of measures include:

✤ Strengthen the ESG Implementation Framework ✤

GlobalWafers’ Corporate Sustainable Development Committee is the core driving force for promoting ESG initiatives, with the Chairperson serving as the Committee Chairperson and CFO Ming-Hui Chien as the Director General. The Corporate Sustainability Committee covers three aspects: environmental, social, and governance. To address various sustainability tasks and promote them more effectively, five subcommittees—the “Sustainable Operations Subcommittee,” the “Green Manufacturing Subcommittee,” the “Sustainable Supply Chain Subcommittee,” the “Social and Corporate Care Subcommittee,” and the “Corporate Governance and Risk Management Subcommittee”—were formed.

• Sustainable Operations Subcommittee

• Green Manufacturing Subcommittee

• Sustainable Supply Chain Subcommittee – Suppliers & Customers

• Social and Corporate Care Subcommittee

• Corporate Governance and Risk Management Subcommittee

Each subcommittee assigns a dedicated member to serve as part of the Sustainable Development Task Force. These members hold ad hoc meetings and discussions on ESG-related projects and issues, establishing smooth communication channels. When encountering cross-departmental and cross-group sustainability projects, the Sustainable Development Task Force coordinates and manages these initiatives.

Additionally, each year, all departments are invited to set ESG goals related to their operations and review the previous year’s progress. Personnel from different departments brainstorm together, focusing on the company’s green commitments, and develop diverse measures to jointly advance corporate sustainability.

Furthermore, GlobalWafers has appointed dedicated personnel with extensive knowledge and expertise in corporate governance to serve as the corporate governance officer, ensuring that the Company adheres to the latest regulations, standards, and best practices in governance.

✤ Continue to promote green manufacturing ✤

GlobalWafers continues to promote green technology and energy-saving concepts. By introducing multiple energy-saving projects, we optimize the effciency of energy and resource usage and achieve outstanding results. Through various improvements at GlobalWafers Zhunan Plant reduced the electricity consumption intensity and greenhouse gas emission intensity per unit product by 23.7% in 2022 compared to 2021. In 2023, energy-saving improvements were made by installing variable frequency drives on the air conditioning chillers and colling water circulation pumps, replacing the ingot pulling process chillers with high-temperature variable frequency chillers, and upgrading the monitoring systems. These upgrades allow the equipment to automatically adjust its operating frequency based on actual demand, thereby reducing energy consumption while further improving energy efficiency. This resulted in an impressive annual electricity savings of nearly 3.09 million kWh and a reduction of 1,530 tons of carbon emissions per year. In addition, we have focused on the most energyintensive parts of the wafer manufacturing process by developing and introducing energy-efficient hot zone designs for ingot pullers, significantly reducing energy consumption in the manufacturing process.

✤ Proactive use of renewable energy ✤

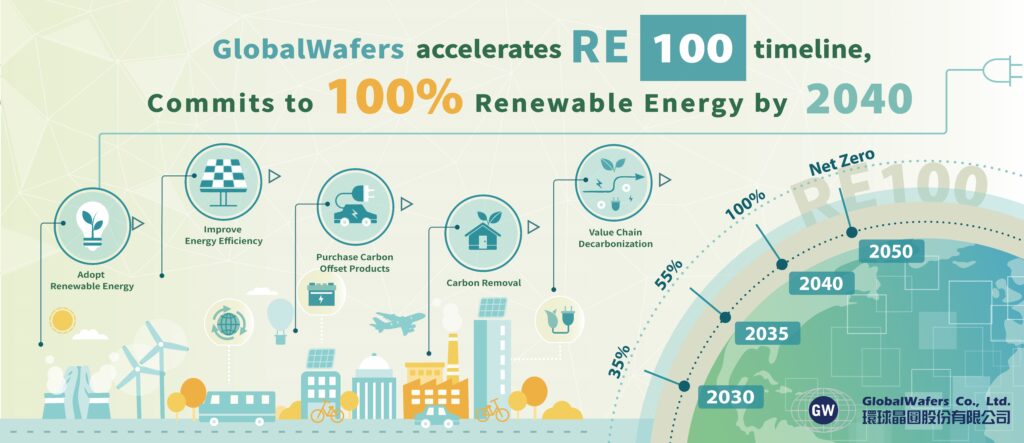

RE100 is a global renewable energy initiative jointly launched by The Climate Group and CDP (Carbon Disclosure Project), gathering the power of enterprises worldwide to promote the use of renewable energy and energy transition. To implement the business philosophy of “Responsible Growth,” GlobalWafers has voluntarily declared since 2021 that it would achieve the goal of 100% renewable energy use by 2050, and officially joined the RE100 initiative in 2022. Facing the challenges of global climate change, GlobalWafers, as one of the world’s leading semiconductor wafer manufacturers, is not only a trusted supply chain partner for its customers but will also contribute to promoting industrial development and environmental sustainability. GlobalWafers proactively advanced its RE100 target timeline by a significant 10 years, and more actively adjusted its phased targets, updating the milestones for the entire group’s renewable energy usage ratio from 20% in 2030, 35% in 2035, 50% in 2040, and 100% in 2050 to 35% in 2030 and 55% in 2035, with the entire group using 100% renewable energy by 2040. Through comprehensively accelerating the increase in renewable energy utilization rates at each operational site and continuously reducing carbon emissions from electricity consumption, GlobalWafers demonstrates its commitment to net-zero carbon emissions and firmly responds to environmental sustainability with practical actions.

To expedite the achievement of its 100% renewable energy target, GlobalWafers is pursuing a dual-track approach. On the operational front, in addition to reducing the energy consumption of existing equipment and continuously optimizing the efficiency of major energy-consuming equipment. Concurrently, production sites worldwide are aligning with the group’s energy transition roadmap. Through a range of initiatives—including diverse strategies such as installing solar panels, introducing alternative clean energy, signing power purchase agreements (PPAs), and acquiring renewable energy certificates (RECs) —is enabling the group to meet its RE100 commitment ahead of schedule. At the same time, GlobalWafers is also leveraging the rich experience of its parent company, Sino-American Silicon Products, in the renewable energy sector and its vertically integrated supply chain to significantly boost the share of green energy usage.

✤ Meeting the global localization trend and reduce the carbon footprint of products ✤

Since its establishment, GlobalWafers has been actively strengthening itself, with operational sites in Europe, the Americas, and Asia, providing localized services to customers. Once the new plant in the United States is completed, GlobalWafers will have a global presence with 18 operational production bases across 9 countries, encompassing one-stop solution from ingot growth to epitaxy on three continents. This distributed global production network brings multiple sustainability benefits. First, a short-distance supply chain helps reduce CO2 emissions from transportation and lowers environmental costs. Secondly, dispersed production sites help to improve risk management and business continuity. Reducing the risks to the overall business caused by natural disasters, geopolitics, and other factors in a single region will help enhance the Company’s business stability.

✤ Sustainable Supply Chain ✤

GlobalWafers places great emphasis on supply chain management to ensure sustainable and responsible operations in the global business environment.

Suppliers

We require all suppliers to sign the Supplier Code of Conduct & Supplier’s Declaration on Compliance with Supplier Code of Conduct before commencing cooperation, clearly expressing their commitment to comply with relevant regulations and ethical standards. The Code includes provisions on anti-bribery, anti-corruption, social and environmental responsibilities, conflict-free minerals, compliance with trade laws, prohibition of infringing products or goods, prohibition of silicon products containing forced labor, and green procurement, among others. In addition, GlobalWafers also conducts supplier integrity assessments to assess transparency, accountability, and risk management capabilities in business practices of suppliers. Through the above measures, GlobalWafers expects its suppliers to engage in business activities with the same legal, ethical, environmental, and quality standards as GlobalWafers.

GlobalWafers practices green procurement, including purchasing environmentally friendly products, local sourcing, and wooden pallet recycling. The Company continuously invites suppliers to join in carbon reduction efforts, implementing “Organizational Greenhouse Gas Inventory (ISO14064-1)” and “Product Carbon Footprint Calculation (ISO14067)” to monitor factory carbon distribution and calculate product carbon footprints. In the future, GlobalWafers will continue to promote the establishment of carbon reduction targets within the supply chain, working together with suppliers to advance sustainable development in the value chain.

Customers

GlobalWafers establishes close and long-term cooperative relations with customers. Before cooperating with customers, we sign non-disclosure agreements to fully protect the sensitive and confidential information of both parties. GlobalWafers is aggressively engaged in quality management activities for full-scale compliance with continued improvement as well as optimized manufacturing process technology in order to enhance product quality. Each plant has established a Quality Improvement Team (QIT) composed of members from all functional departments. The members of the QIT quality improvement team are committed to long-term process research and product quality improvement. The Company has also established the “Process of Customer Complaints Management” to maintain good communications with its customers, as well as effective appealing procedures regarding products and service. We also conduct annual customer satisfaction surveys, using customer feedback as a benchmark for continuous improvement and progress to enhance the competitiveness of our products.

✤ Social and Employee Care ✤

GlobalWafers has established the Human Rights Policy and is committed to creating an equal, safe and dignified workplace. GlobalWafers continues to promote workplace equality and create a friendly workplace by implementing the values of diversity, equity, and inclusion within the Company to create a friendly workplace environment.

The Company’s internal Employee Caring Program (ECP) provides comprehensive care for employees, including the introduction of the Employee Assistance Program Service Center (EAPC) of Hsinchu Lifeline Association. The services cover a wide range of areas including emotional management, interpersonal relationships, legal issues, career development, family and parenting, and financial consultations. The goal is to ensure employees feel secure and confident in their work. GlobalWafers’ employee care measures have been highly recognized, earning the honor of the “2023 Excellent Organization for Promoting Work Equality in the Workplace in Hsinchu Science Park.” Additionally, GlobalWafers’ Japanese subsidiary, MEMC Japan Ltd. received the “Kirari” award from Utsunomiya City. This award recognizes the Company’s active encouragement of female managers’ development, support for childcare and work-life balance, and provision of job opportunities for workers over 65 years old.

The road to sustainable development is full of challenges, and I firmly believe that these challenges also bring opportunities. Technological innovation, changes in market demand, and regulatory trends will all serve as driving forces for our advancement. In the future, GlobalWafers will continue to strive to achieve higher sustainability goals to ensure continuous progress in the environment, society, and corporate governance. GlobalWafers remains committed to responsible growth, actively undertaking the Company’s responsibilities towards society and the environment.

Chairperson and CEO of GlobalWafers

Doris Hsu