Supply Chain Management

- Supplier Assessment Management

- Procurement Policy

- Conflict-Free Minerals Policy

- Sustainable Material Policy

- Green Purchasing

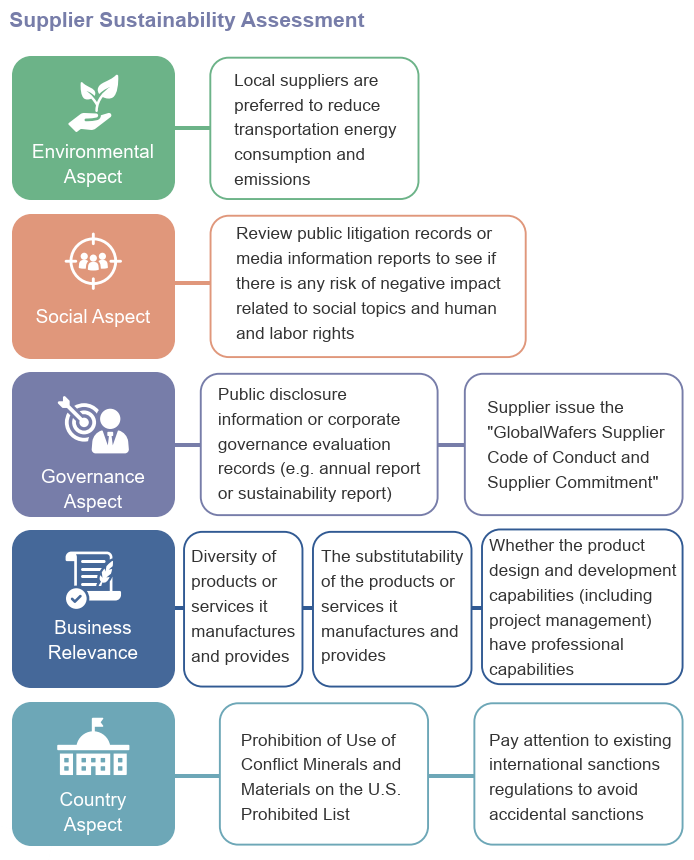

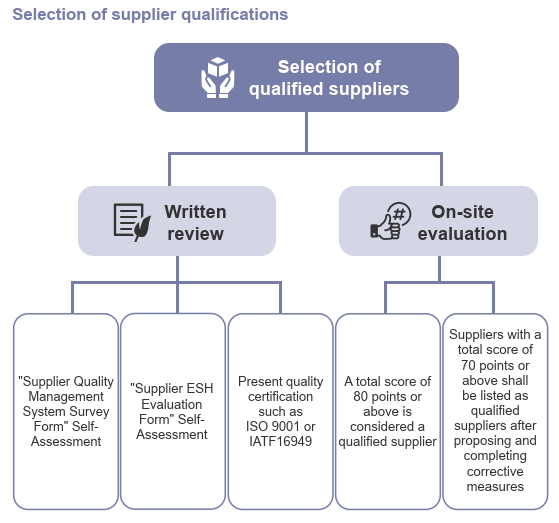

Through appropriate supplier assessment operation, qualified suppliers are carefully defined and selected. Close work relationship and feedback system are also established accordingly to ensure raw material, finished product, half-finished product, fixture and tools, technology service and other labor services all comply with quality, environment, safety, and hygiene requirements. Our qualified suppliers all need to comply with integrity operation principles, with no dishonest behavior records for our suppliers. Each year, we have a supplier assessment team composed of our quality assurance, R&D and other related departments. This team conducts supplier factory audits and document reviews, and interviews suppliers’ management and employees to uncover out issues and rectify accordingly. Related audit records are maintained for inspection.

Document

Download

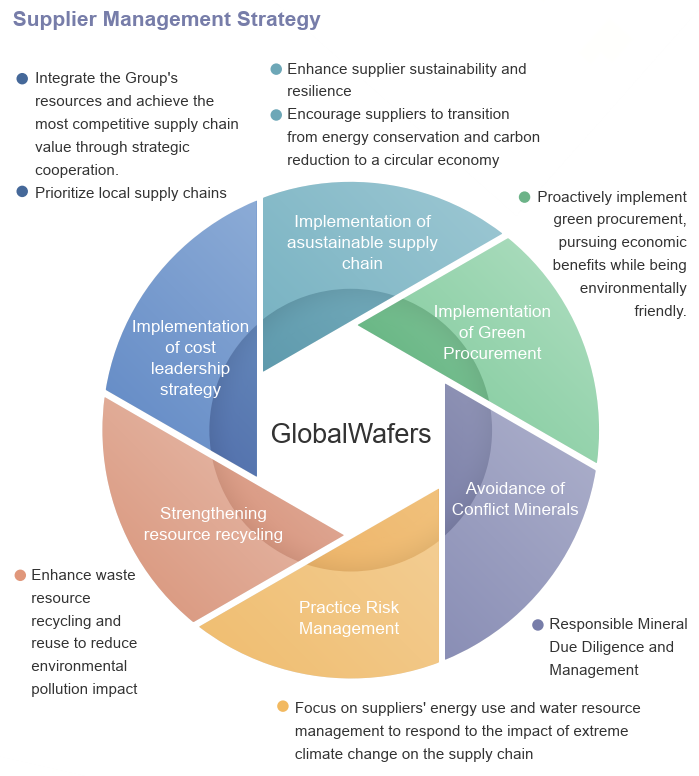

GlobalWafers is committed to responsible sourcing and actively cooperates with supplier partners. At the same time, we pay attention to social and environmental impacts and ensure that the supply chain is equipped with a safe working environment, maintains dignified labor relations, and operates in compliance with ethical standards. We fulfill our corporate social responsibilities to achieve the goal of developing a sustainable supply chain.

Through appropriate supplier assessment operation, qualified suppliers are carefully defined and selected by GlobalWafers. Close work relationship and feedback system are also established accordingly to ensure raw material, finished product, half-finished product, fixture and tools, technology service and other labor services all comply with quality, environment, safety and hygiene requirements. Our qualified suppliers all require to comply with Code of Integrity Management, with no dishonest behavior records. Each year, we form a supplier appraisal team composed of quality assurance, procurement, environmental safety, R&D, and other relevant department members to perform supplier factory audits and document reviews. We also conduct interviews with other supervisors and employees to improve the issues discovered and retain the relevant records for inspection.

GlobalWafers Procurement Policy

- Comply with regulations and adhere to transparent, fair, and honest procurement principles.

- Establish close relationships with suppliers, considering and responding to the procurement interests of stakeholders.

- Promote “responsible mineral procurement” and collaborate with suppliers in response.

- Prioritize the procurement of low-carbon products, promote energy conservation, waste reduction, and green transportation.

- Fulfill social responsibilities, respect human rights.

Anti-Bribery and Anti-Corruption

- Suppliers must comply with applicable laws of the Republic of China and also adhere to the U.S. Foreign Corrupt Practices Act (FCPA), the U.K. Bribery Act 2010, and all other applicable anti-bribery and anti-corruption laws and regulations.

- Suppliers should communicate anti-bribery and anti-corruption conduct to their employees, agents, representatives, suppliers, contractors, and others who transact directly or indirectly with the buyer or represent the buyer in business dealings. Suppliers shall not, under any circumstances, offer, promise, or deliver bribes or any improper benefits to influence the buyer’s transaction decisions.

- Suppliers should regularly self-assess and verify to ensure they are not involved in related party transactions, fraudulent transactions, or any legal evasion or illegal activities.

Social and Environmental Responsibility

- Suppliers should acknowledge, understand, adopt, and commit to complying with the “Responsible Business Alliance Code of Conduct” (hereinafter referred to as “RBA”) and its subsequent updates. The current RBA regulations can be found at: http://www.responsiblebusiness.org/.

- Suppliers should recognize the standards related to labor, health and safety, environment, and business ethics established by RBA, which aims to ensure labor safety and environmental and ethical business practices in the electronics industry or industries where electronic products are a major component. To adopt RBA, suppliers should declare their support for RBA and actively implement its regulations and standards based on the management system in RBA.

Trade Compliance

- Suppliers should continuously track updates to applicable export control regulations to ensure compliance and should fully disclose the applicable export control regulations for the products or goods supplied, transferred, or delivered to the buyer.

- Suppliers shall not engage in any illegal, improper, anti-competitive, or unfair business practices.

Non-Infringing Products or Goods

Suppliers must ensure that all products or goods supplied, transferred, or delivered to the buyer do not directly infringe, indirectly induce, or assist in infringing any domestic or foreign intellectual property rights of third parties.

Prohibition against Silica-Based Products Involving Human Rights Violation

- Supplier shall enhance its scrutiny regarding anti-forced labor compliance by documenting the source and origin of silica-based inputs within Supplier’s supply chain. Such documentation (e.g. certificate of input origin, list of input suppliers) shall be duly provided to Buyer upon request in response to customs authority’s investigation (e.g. U.S. CBP detention under Withhold Release Order) of any item involved with Supplier’s product/good.

- Supplier shall warrant that, any of the silica-based products, components or materials supplied, transferred or delivered to Buyer must not be made by using forced labor, child labor, or any measure in violation of human rights.

- Supplier shall also warrant that, any of the intermediate goods or finished goods supplied, transferred or delivered to Buyer must not incorporate any silica-based product, component or material which is incompliant with the foregoing section, and must not be derived from or produced by using any silica-based product, component or material which is incompliant with the foregoing section.

- Supplier shall periodically update and review information regarding silica-related manufacturers subject to forced labor allegation. Buyer further encourages Supplier, on a voluntary basis, to mitigate compliance risk in its supply chain by sourcing polysilicon materials outside of Xinjiang. (For a convenient reference, certain entities in violation of human rights may be found on: Department of Commerce (DOC) Entity List and Department of Homeland Security (DHS) UFLPA Entity List. )

GlobalWafers Conflict-Free Minerals Policy

GlobalWafers is committed to conducting thorough investigations of its supply chain to ensure that the sources and supply chains of gold (Au), tantalum (Ta), tungsten (W), tin (Sn), cobalt (Co), and mica used in its products comply with the “OECD Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas” or other equivalent and recognized due diligence frameworks for conflict-free minerals, thereby upholding the principles of human rights respect and protection. As an essential and integral part of its sustainability strategy, GlobalWafers has established the following guidelines to clearly communicate the specific requirements of its conflict-free minerals policy to its supply chain.

- Supplier shall recognize that armed rebel organizations in the Democratic Republic of the Congo (DRC) and its surrounding regions operate through metal mining and trading invoke serious social and environmental problems, including human right violations, armed conflict, and international disputes.

- As a corporate citizen responsible for protecting human rights and ameliorating armed conflicts in DRC and its surrounding regions, Supplier is required to take due diligence within its supply chain to assure “Conflict-Free Minerals” with respect to gold (Au), tantalum (Ta), tungsten (W), tin (Sn), cobalt (Co), mica used in its products sold, transferred or delivered to Buyer are not derived from or sourced from the foregoing areas.

- Supplier shall acknowledge that areas not confirmed to be “Conflict-Free Minerals” include direct exports from the DRC, as well as exports through Angola, Burundi, Central African Republic, Republic of Congo, Rwanda, South Sudan, Zimbabwe, Uganda, Tanzania, Kenya , and Zambia (countries of whom the U.N. Security Council note are global export routes for DRC-mined minerals).

- Supplier shall adopt a policy and exercise due diligence on the source and management of the gold (Au), tantalum (Ta), tungsten (W), tin (Sn), cobalt (Co), mica in the products they manufacture in a way consistent with the “Organization for Economic Co-operation and Development (OECD) Guidance for Responsible Supply Chains of Minerals from Conflict- Affected and High-Risk Areas” due diligence framework to assure that such minerals are conflict-free.

- If the products provided by Supplier involve usage of gold (Au), tantalum (Ta), tungsten (W), tin (Sn), cobalt (Co), or mica as raw materials, Supplier shall complete and submit to Buyer the Conflict Minerals Reporting Template (CMRT) or Extended Minerals Reporting Template (EMRT), which may be downloaded from the RMI website.

GlobalWafers Sustainable Material Policy

I. Policy Statement

GlobalWafers commits to sustainable development by responsibly sourcing, using, and managing materials. We pledge to follow environmental laws, international standards, and biodiversity principles to reduce the environmental impact of our supply chain and operations.

II. Policy Principles

1. Environmental Priority

We prioritize sourcing materials with environmental certifications and aim to use low-carbon

sources identified through life cycle assessments. This supports resource circulation and long-term sustainability.

2. Supplier Qualifications

All raw material* suppliers must have valid environmental or sustainability certifications. They

must also provide regular reports on environmental performance and carbon footprint.

3. Source Transparency

Suppliers must share information about where their raw materials come from. This ensures legality, avoids conflict minerals , and supports traceability across the supply chain. We review this information regularly.

4. Reducing Environmental Impact

We work to improve how efficiently we use materials, recycle waste throughout the

manufacturing process, and implement packaging recovery to reduce our overall environmental impact.

5. Continuous Improvement

We review this policy regularly and update it based on evolving regulations, trends, and best

practices. We also provide sustainability training to employees and suppliers to raise awareness and improve performance.

III. Oversight and Auditing

GlobalWafers regularly audits suppliers to monitor their compliance with the Supplier Sustainability Standards. If we find any issues, we give clear guidance and set a deadline for corrective actions. If a supplier continues to fall short, we reserve the right to adjust or end the business relationship.

IV. Policy Communication

We publish this policy on our company website and share it through proper communication channels to ensure that all stakeholders understand and support our policy.

*Raw material in this context shall mean polysilicon.

For each citizen’s fulfilling responsibility, GlobalWafers Co.,Ltd. aggressively involve into green purchasing, require suppliers must follow below principles:

- The supplied goods comply with government laws both domestically and abroad (such as RoHS, REACH and WEEE and so on) of the environmental protection product.

- Prior to purchase the office affairs, computer facilities, electronic equipments with Green Mark (i.e. Energy Saving, Water Saving, Green Building Materials) which announced by official authorities to protect the environment.

- Suppliers shall reveal the third party impartial unit test report to assure as without the use of hazardous substances when necessary.