In recent years, ESG has become an essential benchmark for evaluating corporate resilience and sustainable development. Facing the dual challenges of energy transition and climate change, governments worldwide have introduced energy-saving and carbon-reduction policies. Beyond meeting regulatory requirements, companies must also take concrete actions to improve their environmental performance. As one of the world’s top three semiconductor wafer suppliers, GlobalWafers fully recognizes the critical role of green transformation in sustainable growth. Accordingly, the company has been promoting energy efficiency improvements and equipment replacement projects across its production sites to gradually reduce energy consumption and carbon emissions.

At the Taisil branch, most facility and crystal-growing equipment has been in operation for nearly 30 years since the plant was established in 1995. Although well maintained, prolonged use has inevitably led to declining efficiency, creating a noticeable gap compared with new-generation high-efficiency equipment. To ensure energy efficiency in operations and advance green manufacturing, the company launched a large-scale energy-saving equipment upgrade project.

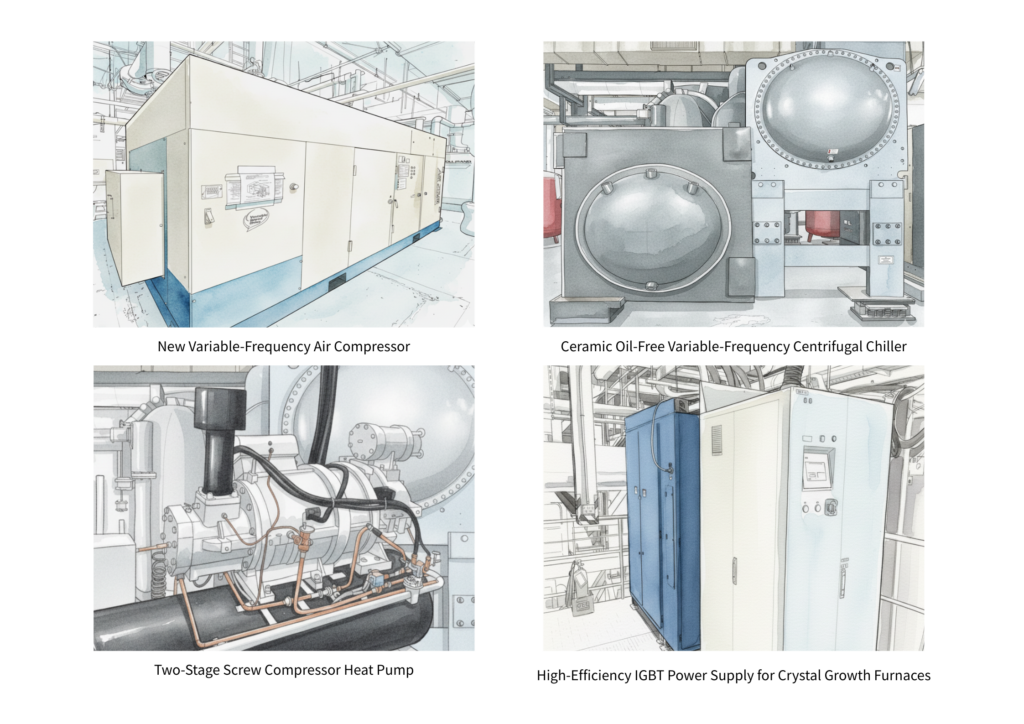

This project covers several key equipment upgrades:

- Air Compression System – Three aging 200-horsepower fixed-speed screw compressors were replaced with a single 580-horsepower variable-speed screw compressor. The new system automatically adjusts operating speed based on demand, reducing unnecessary energy consumption.

- Chilled Water System – Outdated fixed-speed chillers were replaced with ceramic oil-free variable-speed centrifugal chillers. This single upgrade alone delivers annual savings of over 3 million kWh of electricity and more than 1,500 tons of CO₂e reduction, yielding highly significant results.

- Boiler System – A 580kW variable-speed two-stage screw compressor heat pump replaced the traditional natural gas boiler, cutting fuel consumption, improving energy conversion efficiency, and reducing carbon emissions.

- Crystal-Growth Power Supply – SCR-controlled power modules were upgraded to IGBT-controlled modules, offering faster response and more precise control. This not only improves energy efficiency but also enhances the stability and yield of the crystal growth process.

Through this project, the Taisil branch is achieving the following annual outcomes:

- Electricity Savings – 4,707,799 kWh saved annually, equivalent to the annual electricity use of about 1,130 households.

- Carbon Reduction – 2,826 metric tons of CO₂e emissions reduced annually, equivalent to the carbon absorption capacity of 7.3 Daan Forest Parks (a 26-hectare urban park in Taipei, Taiwan) in one year.

This initiative not only reduces energy consumption and carbon emissions in operations but also demonstrates the company’s commitment to embedding ESG principles into green manufacturing. By upgrading equipment and optimizing energy efficiency, GlobalWafers further strengthens its sustainable competitiveness, establishes a best-practice model for cross-site knowledge sharing, and advances the semiconductor industry toward a low-carbon future.