As the world faces the challenges of climate change and resource sustainability, green manufacturing has become a key direction for industrial development. Against this backdrop, GlobalWafers continues to deepen its commitment to green manufacturing and has recently implemented a smart wire-break detection system in its slicing machines. This system enables real-time monitoring and anomaly prevention, which not only facilitates the smooth advancement of fine-wire slicing process development but also effectively reduces industrial waste generation and lowering carbon emissions, demonstrating the Company’s dual commitment to smart manufacturing and sustainable development.

To improve material utilization, reduce industrial waste, and advance environmental sustainability, GlobalWafers has promoted fine-wire slicing technology. However, in wafer processing, wire breaks in slicing machines often cause roller groove deformation, leading to ingot scrap and raw material waste. Traditional mechanical sensors lacked sufficient sensitivity to detect wire breaks immediately and halt operations, and current sensor would also be affected by cutting water, resulting in persistent material losses.

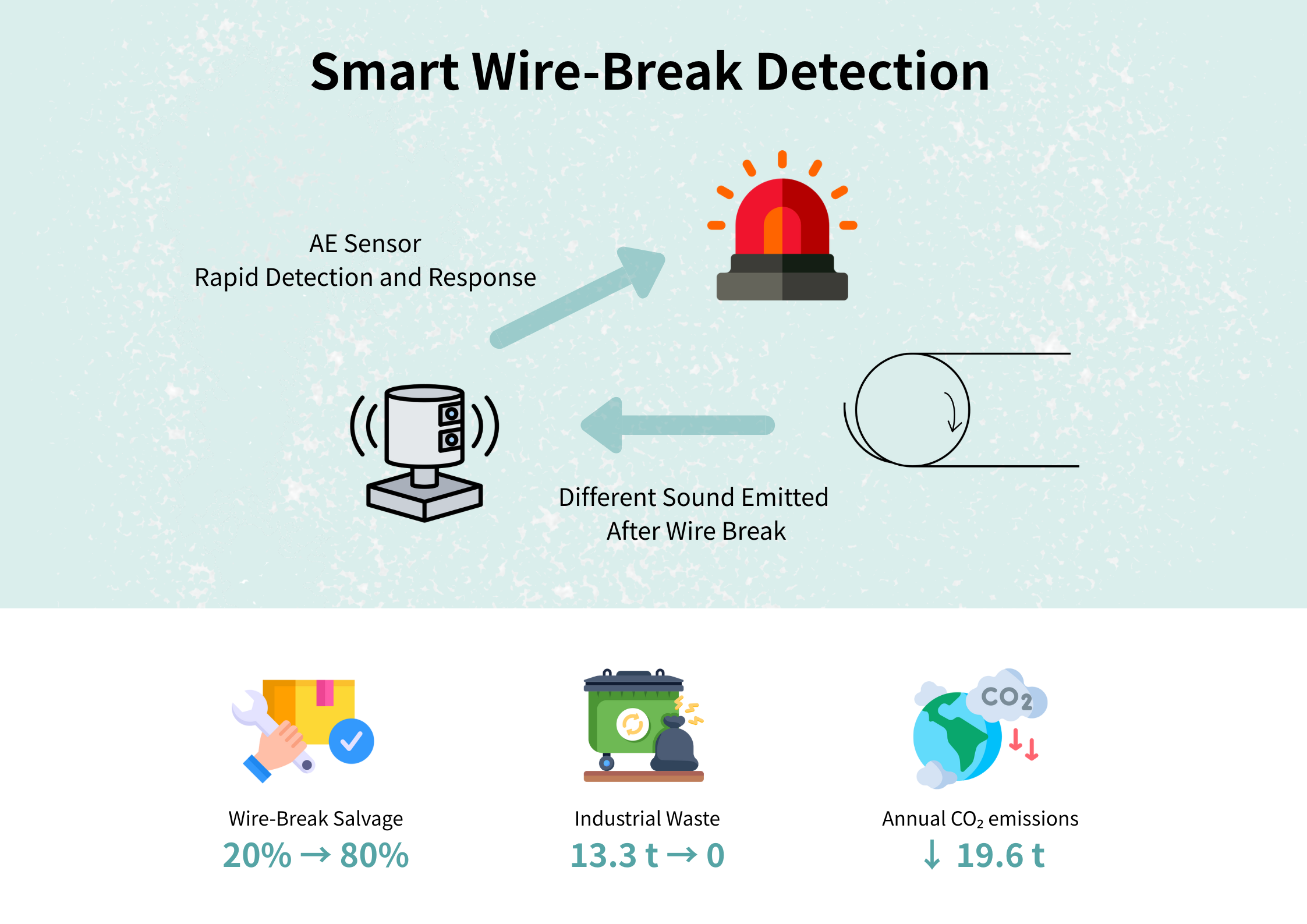

GlobalWafers’ newly adopted smart wire-break detection system incorporates an acoustic emission sensor in addition to existing mechanisms. By monitoring acoustic signals in real time, the system can rapidly identify wire break events and instantly trigger machine responses, significantly shortening reaction times. This innovation effectively resolves the limitations of traditional sensors, reducing ingot losses and equipment damage while advancing the Company’s waste- and carbon-reduction goals.

The project has delivered three major benefits:

- Reduced Scrap: Yield recovery rate from 20% to 80% following a wire breakage, significantly lowering wafer scrap and material waste.

- Zero Waste: The multi-wire slicing station, which previously produced an average of 13.3 tons of cutting oil waste each month, has now achieved zero output after adopting the fine-wire slicing process.

- Carbon Reduction: Annual CO₂ emissions have been reduced by 19.6 tons.

This system not only enhances process stability and reliability but also effectively minimizes resource waste and contributes clear environmental benefits, underscoring the GlobalWafers dual-track commitment to smart manufacturing and sustainable development.