GlobalWafers places great importance on environmental management and continues to upgrade facility operations through technological innovation and process optimization. The Zhunan Plant II recently launched the “Gallium-Containing Wastewater Diversion and Recycling Project,” representing a new milestone in the company’s efforts to strengthen pollution control and resource reuse.

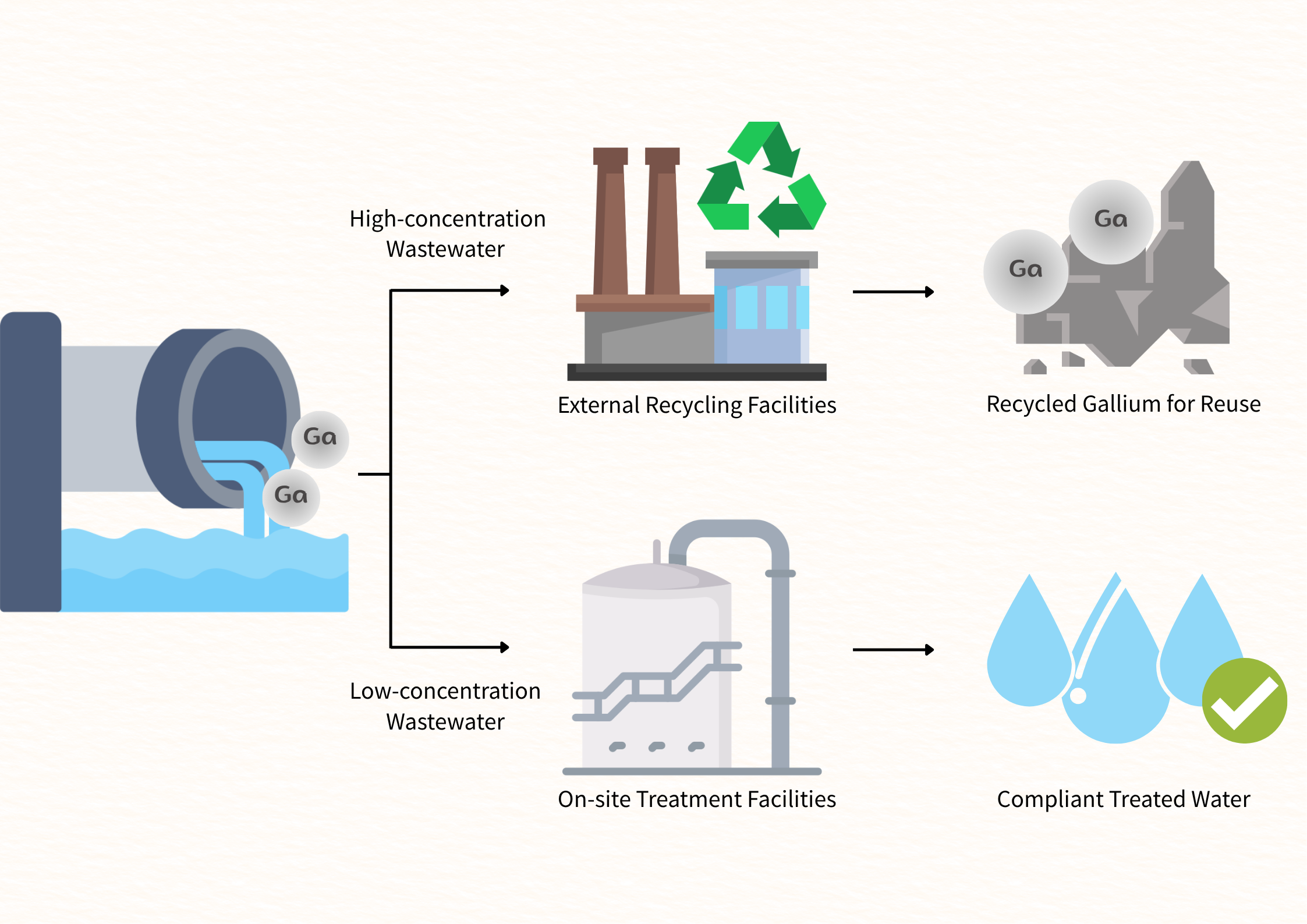

In line with sustainable development strategies, the project team adopted a dual approach combining source reduction and end-of-pipe collection to promote waste reduction and resource circulation. Gallium dust generated during production is first captured through dust collection systems, preventing it from entering downstream cleaning processes. Wastewater samples are then analyzed to determine concentration distributions. High-concentration gallium wastewater is diverted and collected separately for performance testing and treatment by qualified recycling partners, while low-concentration wastewater is managed by the plant’s treatment facilities to reduce system load and ensure stable compliance. Through processes such as chemical coagulation and electrolysis, the external partner not only treats the wastewater effectively but also recovers gallium metal of economic value.

This model has significantly enhanced the plant’s processing efficiency while ensuring effective cost control. The project’s demonstrates positive benefits. It is expected to deliver stable cost savings of approximately NT$250,000 per month, equivalent to about NT$3 million annually. This not only shows a substantial improvement in operational efficiency but also provides tangible economic returns.

By implementing this project, GlobalWafers has moved beyond the traditional model of relying solely on centralized treatment. Supported by data-driven verification, active collaboration with capable partners, and the establishment of a diversion management system, the initiative not only reduces treatment burdens but also ensures effluent quality consistently meets the park’s regulatory standards to reduce environmental impact , while creating added value through resource recovery. This practice highlights the company’s ability to balance environmental compliance, resource circularity, and economic performance, and it provides a replicable model for other plants to further reinforce the sustainability and resilience of overall operations.