GlobalWafers is committed to energy conservation, waste reduction, and resource circulation, actively implementing green manufacturing practices and continuous sustainability initiatives. Recently, the company introduced an acid recycling mechanism at the production level. Through system redesign and process optimization, the initiative enables the reuse of acids, effectively reducing both waste treatment and fresh acid consumption costs while demonstrating the company’s concrete actions in implementing the concept of sustainability through green manufacturing and advancing ESG development.

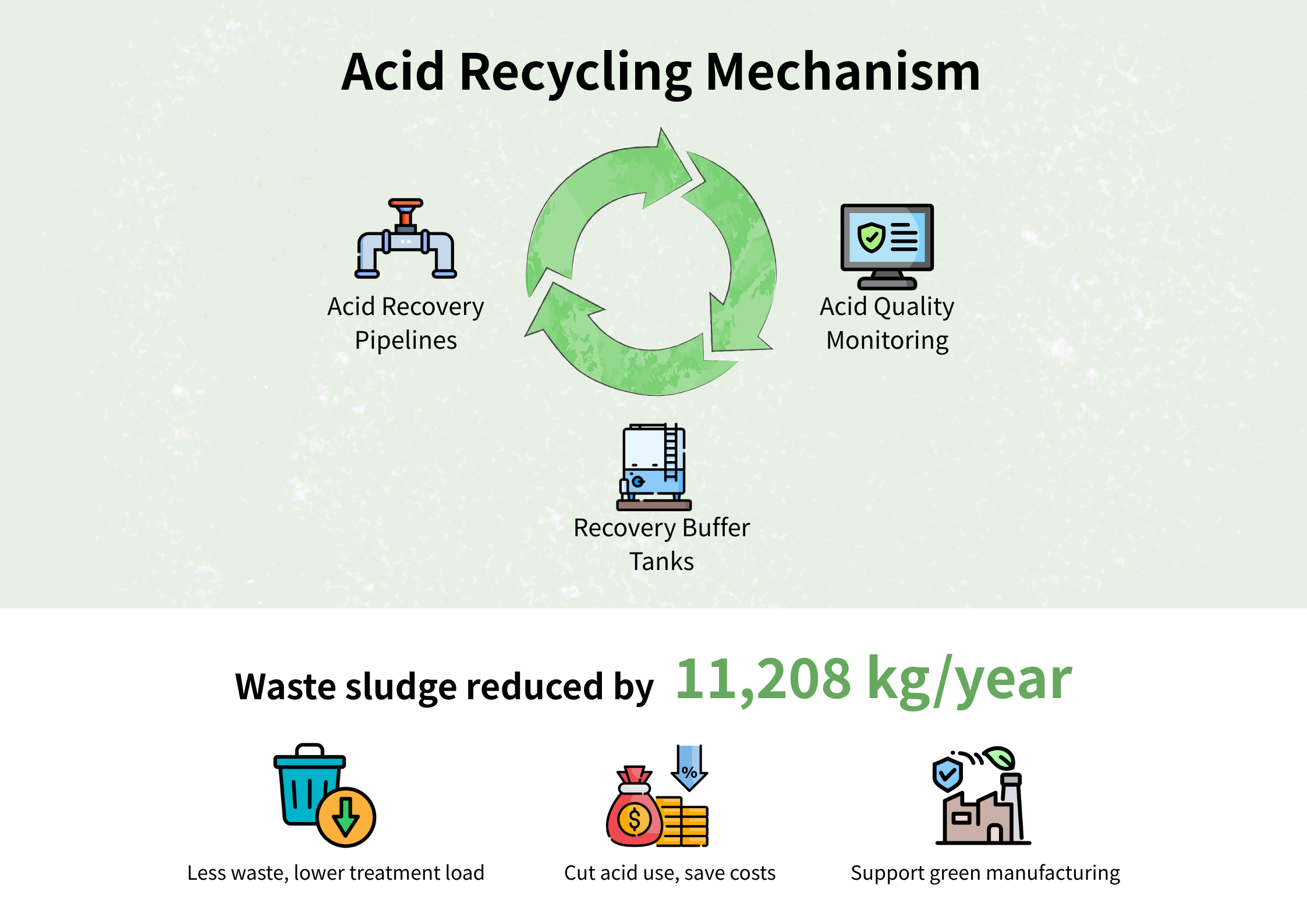

In the past, when certain equipment was shut down, acids with remaining usable value inside the machines were often discharged directly to the wastewater treatment facility. The resulting waste liquids and sludge were classified as industrial waste, leading to additional treatment costs and environmental burdens. To address this issue, the company redesigned the recovery pipelines, channeling the spent acid into recovery buffer tank. Once the equipment restarts, the stored liquid is fully reintroduced into the production process. A quality monitoring system ensures that the recycled acid consistently complies with process standards, allowing for safe, stable, and efficient reuse.

Since its implementation, the project has already delivered significant results. Estimates show a reduction of approximately 934 kilograms of waste sludge each month, equivalent to an annual decrease of 11,208 kilograms. This achievement not only alleviates the pressure on waste treatment systems but also generates three key benefits:

- Environmental: Lower discharge of waste liquids and sludge, reducing the load on treatment facilities and mitigating environmental impact.

- Operational: Reduced consumption of fresh acid and lower disposal expenses, creating cost savings.

- Sustainability: Reinforces the company’s commitment to green manufacturing and environmental responsibility.

This recycling mechanism represents more than the optimization of a single process and has the potential to be extended across similar equipment within the group. Looking ahead, GlobalWafers plans to broaden the application of this technology and further explore waste liquid regeneration methods and acid life-cycle monitoring. These efforts will allow for more precise tracking of acid usage, longer service life, higher recovery rates, and ultimately the circular economy goal of minimizing waste generation and maximizing resource circulation.

Through this recycling mechanism, GlobalWafers once again demonstrates its strong commitment to environmental stewardship and contributes to the green transformation of the semiconductor industry. The company will continue refining its processes, improving efficiency, and building a high-performance, low-carbon, and sustainable manufacturing model, working alongside global customers and partners to create a more competitive and sustainable future.