In recent years, ESG has become a key benchmark for corporate operations and sustainable development worldwide. As global governments actively promote energy-saving and carbon-reduction policies to combat the pressing challenges of energy transition and climate change, companies are expected not only to comply with regulations but also to demonstrate proactive efforts and determination.

As one of the world’s top three semiconductor wafer manufacturers, GlobalWafers recognizes the vital role of technological innovation in driving sustainable transformation. GlobalWafers continues to implement ESG improvement initiatives across our facilities and invests in the development of advanced insulation materials to enhance energy efficiency. By embedding ESG principles into its core green manufacturing operations, GlobalWafers further strengthen its sustainable competitiveness and reaffirms its long-term commitment to responsible growth.

To achieve sustainability goals, GlobalWafers has in recent years prioritized improving efficiency in energy-intensive manufacturing processes, with a particular focus on optimizing the crystal growth process for silicon ingots. This process is centered on the Czochralski (CZ) method, which requires maintaining a high-temperature environment of over 1400°C to steadily grow crystals upward from a seed crystal over a prolonged period. Due to the intensive energy demands of this process, it accounts for a significant portion of total power consumption at the facility and has thus been designated a priority for energy efficiency improvement.

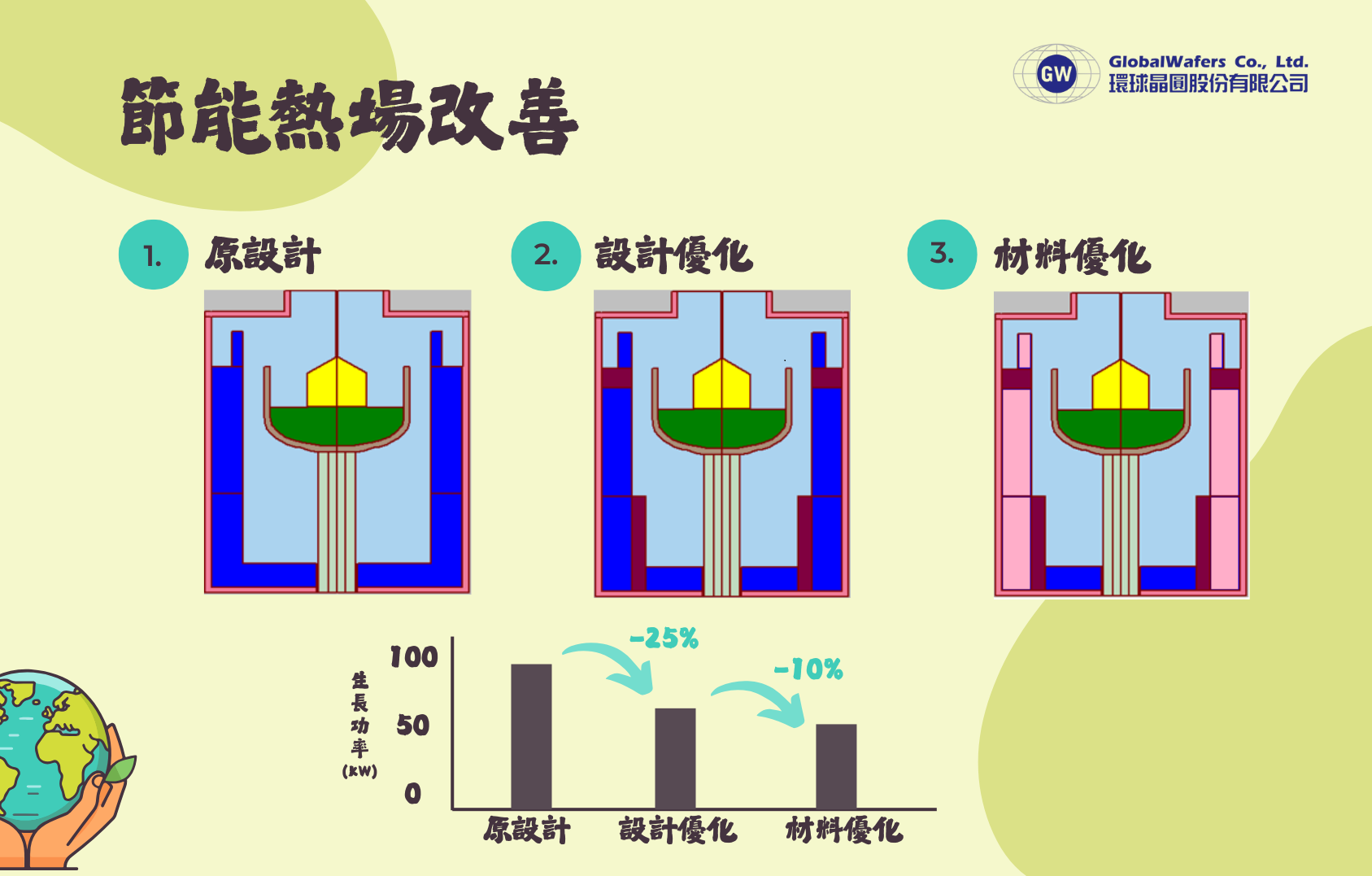

To effectively reduce power consumption, GlobalWafers successfully developed a new energy-saving thermal field module several years ago. By optimizing the heating structure of the furnace, enhancing temperature uniformity in the thermal field, and improving material reflectivity, this innovation has reduced the average power consumption per crystal-pulling furnace by approximately 25%. This module has now been fully implemented across all current crystal growth equipment and operates stably, significantly enhancing energy efficiency and supporting the company in achieving its carbon reduction targets.

Building on this foundation, GlobalWafers continues to optimize the module design by further researching and improving key materials. The company has introduced a low thermal conductivity insulation material to replace the previously used rigid carbon fiber insulation. In addition to superior insulation performance, the new material is also highly flexible, allowing for customized sizing to fit different crystal growth furnace models. Testing shows that this upgrade can further reduce energy consumption by an additional 5–10% on top of existing savings. Furthermore, the new material simplifies the production process, significantly shortens fabrication time, and cuts material costs by over 50%. This innovation not only achieves greater energy efficiency, carbon reduction and cost control, but also demonstrates the company’s concrete actions toward process improvement and environmental sustainability.

Looking ahead, GlobalWafers will continue to drive sustainable transformation through technological innovation, broaden the application of energy-saving technologies, and deepen its ESG practices in areas such as process optimization and carbon emission management, making meaningful contributions to a low-carbon future for the semiconductor industry.